Metallurgy

Metallurgical enterprises

Data transmission devices over the radio channel allow you to read the readings, even in low visibility (smoke, dust), to make in the memory of scales a mass of containers, even if the scales are out of operator’s visibility area.

Massive high-strength construction and protected from electromagnetic interference and increased temperature electronic crane scales KGW is designed for prolonged operation in complex production conditions, in that account while moving weights with cargo. Crane scales allow weighing large products, rolling mill, forging equipment and cargoes with any geometric dimensions and weight in metallurgical enterprises, as well as perform control and test of cranes and mobile transport systems.

Crane scales for weighing of long and large cargoes can be used as Master-Slave system, consisting of two or more weights of the same modification, information exchange between them is carried out over the radio channel.

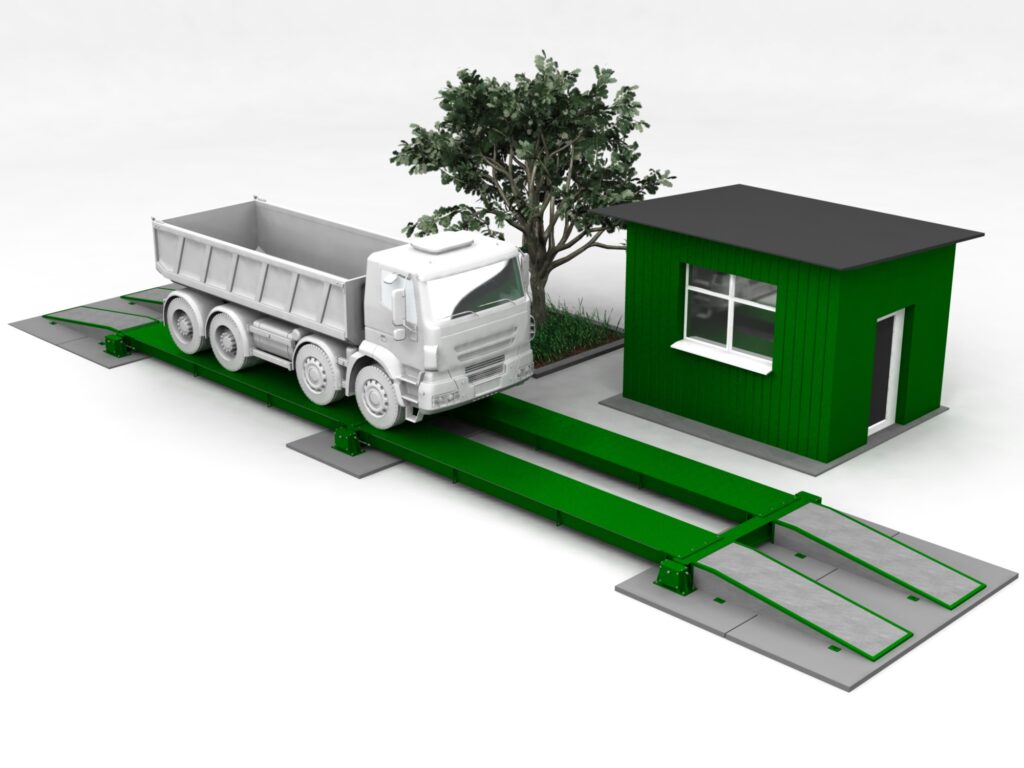

Improved reliability of the foundations, electronics and metal of weighbridges KODA-a allow to conduct intensive weighing heavier cars without loss of accuracy.

Even short-term failure of scales at the enterprise with a continuous cycle of production causes significant losses. Maintenance and operational repairs reduce customer’s costs. .

The design of scales KODA-V allows weighing special railcars(scrubs, pellets, slag, hoppers, etc.) including increased load-lifting without loss of accuracy.

Improved reliability of the foundations, electronics and metal scales KODA-a allow to conduct intensive weighing heavier cars without loss of accuracy.

Various manometers and thermometers, as well as electronic pressure meters and temperatures in various designs for use in tough technological conditions.

Coordinate-measuring hands Hexagon MI ROMER for fast and mobile geometry control or 3D-modelling of parts in metallurgy.

Laser trackers Hexagon MI Leica for high precision volumetric measurement at a distance of 160 meters with a precision of ± 15 mm + 6 mm/M. These systems are used to measure large products, rolling, large forging and other dimensional equipment.

Modern contactless radar levelmeasures successfully work in large reservoirs with bulk materials for strong dust formation. Such levels are able to unite into systems with centralized control and indication.