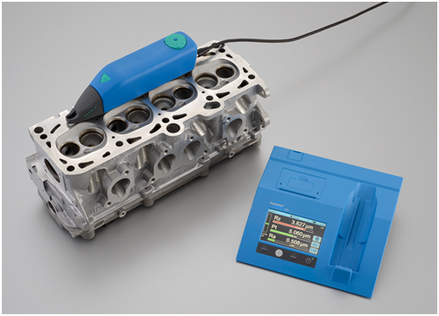

HOMMEL TESTER W20

Producer:

- JENOPTIK Industrial Metrology Germany

The 2013 model, replaced the world-renowned modification of the Hommel-Tester T1000 Wave TKU. This device uses the most modern technology of instrument making.

A network-independent device for mobile and stationary measurement of surface roughness, accuracy class 1 (highest) to DIN 4772.

| Accuracy class according to DIN 4772: | 1 (highest) |

| Probe: | TKU 300 / 600 |

| Measuring range: | ± 320 mkm ; ± 600 mkm |

| Units of measurement: | mkm / mkinch (optional) |

| The maximum length of the tracing, mm: | 20 |

| The length of the tracing according to ISO / JIS, mm: | 1,5/4,8/15 |

| The length of the tracing according to MOTIF, mm: | 0,64 / 3,2 / 16 |

| Cutoff step mm: | 0,08 / 0,25 / 0,8 / 2,5 / 8,0 |

| Filters: | EN ISO 11562: Gaussian filter, EN ISO 16610-21: Gaussian filter,EN ISO 13565-1:Rk filter parametersEN ISO 3274: λs filter |

| Speed of tracing, mm / sec: Return speed, mm / sec: 3 |

0,15 / 0,5 / 1 3 |

| The interval between the points min, mkm: | 0.5 (9600 points with the path length 4.8 mm) |

| Battery Type: | Lithium-ion |

| Number of measurements per battery charge: | 800 (without print, with a length of tracing 4.8 mm) |

| Battery charging time, h: | 4 |

| Built-in Memory: | 2000 measurement cycles / options;500 profiles |

| Measuring programs: | 7 measuring programs, 1 measuring program for testing |

| Process temperature ⁰С: | +5 … +40 |

| Dimensions H×W×L mm:The base unit The moving Waveline 20 |

224 × 225 × 70245 × 54 × 75 |

| Mass, g: The base unit The moving Waveline 20 |

10801100 |

| Interfaces: | USB |

| Power supply voltage, V: | 100 … 264 |

| Measured parameters | |

| Roughness parameters, ISO 4287: | Ra, Rz, Rmax, Rt, Rq, RSm, Rp, Rv, Rsk, Rku, Rdc, Rdq, RzISO, Rmr, Rmr(c), C(Rmr), Pt, Pz, Pa, Pc, Pp, Pv, PSm, Pq, PSk, Pku, Pdq, Pdc, Pmr, Pmr(c), C(Pmr) |

| Basic parameters of roughness, ISO 13565-1, -2: | Rk, Rpk, Rvk, Mr1, Mr2, A1, A2, Rpk*, Rvk* |

| Parameters MOTIF, ISO 12085: | R, AR, Rx, CR, CL, Nr, CF |

| Parameters ASMB46: | Rpm |

| Parameters JIS B601 (2001): | Rz-JIS |

| Parameters DIN EN 10049: | RPc |

| Parameters Daimler MBN 31007: | R3z |

| Specifications of built-in printer | |

| Print Method: | Thermal matrix |

| Paper / print width, mm: | 57 ± 0,5 / 48 |

| The diameter of the paper roll, mm: | 31 |

| Resolution: | 8 dots / mm, 384 dots / line |

| Printing: | measurement conditions, the parameters of the roughness profile, Abbott curve, statistics. |

Functional features of the profilometer:

Context management using the touch screen:

- 8 stored measuring programs;

- Function keys for 4 basic functions;

- Evaluation of all major modern roughness parameters (see Technical Characteristics);

- Wide opportunities for assessing the permissible tolerance values (tolerances);

- Quick and convenient input of additional measurement parameters via the touch screen;

- Clear display of measurement results;

- Displays the results on the screen: roughness parameters, profile type (profilogram), interactive curve Abbott (a fraction of the material curve), general statistical functions.

Built-in roughness measure:

- The roughness control measure, reliably stored in the main W10 block, is protected from damage;

- Checking the measuring device at any time as needed by the operator;

- Stable measurement reliability;

- A predefined measuring program for checking the measuring device with the specified nominal values of the measure.

Built-in printer:

- Print measurement results at the measurement site;

- Easy paper loading function;

- Print measurement results with an estimate of the profile error, the Abbot curve, additional information and statistics.

HS300 rack with granite base (option):

- Accurate positioning of the touch probe on the surface of the workpiece;

- The height adjustment range is 300mm;

- Rotating device ± 180 °.

EVOVIS mobile software (option):

EVOVIS mobile – a program for estimating the roughness and contour.

The software is easy to use and offers a standardized interface for measuring roughness and contour, regardless of the configuration of the device. Simple icons supported by the comprehensive help function allow the user to use effective measurement and evaluation tools in accordance with their own requirements.

Special features of EVOVIS mobile:

- Specially developed software for working with portable measuring devices;

- Online mode: the management of W5, W10 or W20 connected to the PC is performed directly by the software;

- Offline mode: the profile settings and data stored in the W5, W10 or W20 memory are transferred to the PC for further evaluation through software capabilities;

- Individual creation of a plan for testing;

- Master of the choice of measurement conditions;

- More than 90 parameters for estimating ripple and roughness in accordance with EN ISO 4287, as well as other ISO and national standards (ASME, DIN, JIS, Motif, etc.);

- Free print protocol design;

- Electronic archiving of measurement protocols in pdf format and automatic saving function.

No accessories for this product.