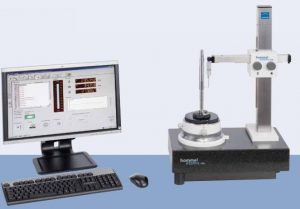

HOMMEL-ETAMIC F435/455

Producer:

- JENOPTIK Industrial Metrology Germany

Measuring station (roundness meter) HOMMEL-ETAMIC F435 / 455 is designed to control the basic parameters of the deviation of the shape and location for the bodies of revolution after machining.

Basic functionality:

- Rapid automated alignment of the measured part on the roundness meter table;

- Automatic measure mode of the parts;

- 3 motorized measuring axes provide high measurement speed;

- Accurate and reliable measurement of almost all parameters of shape deviation and surface arrangement;

- Presence of various fixing accessories for solving various measurement tasks;

- The Russified and intuitive interface of the TURBO FORM accounting software.

Specifications:

| Measuring range | |

| Distance between the axes C and Z, mm: | 325 |

| Max measured diameter, mm: | 430 |

| Max measured height, mm: | 350 / 550 |

| Axis of rotation (axis С) | |

| Table diameter, mm: | 250 |

| Aligning the part: | automatic |

| Error deviation from the roundness of μm + μm / mm height measurement, mkm: | 0,02 + 0,0005 |

| Error deviation from the roundness of μm + μm / mm height *measurement, mkm: | 0,01 + 0,00025 |

| Error of axial runout at μm + μm / mm radius, μm: | 0,03 + 0,0005 |

| Error of axial runout at μm + μm / mm radius*, μm: | 0,015 + 0,00025 |

| Centering range, mm: | ± 2 |

| Range of leveling, °: | ± 0,6 |

| Type of bearing: | pneumatic |

| Measuring and positioning speed, rpm: | 1 – 12 |

| Max load, N: | 400 |

| Vertical axis (axisZ) | |

| Measuring range, mm: | 350 / 550 |

| Straightness error / 100 mm, μm: | 0,15 |

| Straightness error in the whole range, μm: | 0,3 / 0,4 |

| Nonparallelism of C and Z axes for the entire measuring range, μm: | not more than 0,8 / 1,3 |

| Measuring and positioning speed, mm/s: | 0,2 – 23 |

| Collision protection: | yes |

| Horizontal axis (axis R) | |

| Measuring range, mm: | 220 |

| Straightness error / 100 mm, μm: | 0,3 |

| Straightness error in the whole range, μm: | 0,6 |

| Non-perpendicularity of C and R axes for the entire measuring range, μm: | not more than 1,2 |

| Measuring and positioning speed, mm/s: | 0,2 – 14 |

| Dimensions / weight of the measuring system | |

| Length, mm: | 790 / 1010 ** |

| Width, mm: | 510 / 650 *** |

| Height, mm: | 960 / 1160 |

| Weight, kg: | 230 / 300 |

All accuracy characteristics are given in accordance with DIN 1101 and at a temperature of 20 ± 1 ° C.

Measured deviation from roundness with filter 0-15 S / r; 6 rpm; LSC.

Measured deviation from straightness with cutoff of pitch 2.5 mm; 100 mm / min; LSS.

* – value of max. deviations for the reference circle LSCI, filter 0-15 S / r; 6 rpm.

** – the value is given for the long axis R.

*** – the value is given taking into account the protective box of the servo drives.

HOMMEL-ETAMIC F435/455kit:

- Precision rotary table on pneumatic bearings, with automatic centering and alignment of parts up to 40 kg;

- Vertical motorized measuring axis Z = 350/550 mm;

- Horizontal motorized measuring axis R = 220 mm;

- The new generation sensor FT1.1 with a range of ± 1000 μm is equipped with a magnetic holder for quick change of the probe arms;

- Tool table GTF3 with a spring damper platform and a cut-out in the worktop for embedding a granite base;

- PC with Windows7, network card, DVD drive, mouse, 22 “TFT monitor, printer;

- TURBO FORM software in Russian;

- Pneumatic preparation module, including pressure reducer, 0 – 10 Bar manometer, 5 μm coarse filter, 0.5 μm fine filter and membrane dehydrator;

- Manufacturer´ s calibration certificate;

- User´ s manual;

- Training of the customer´s personnel.

Additional options:

- Measurement of roughness and ripple (in combination with the GTF3 table and pneumatic vibration suppression system);

- The motorized rotary module MDS provides measurement with automatic tilt of the sensor FT1.1 at an angle of 0 – 90 ° and rotation along its axis in the range 0 – 270°;

- Tool table GTF3 with pneumatic damping system;

- Precision clamping chucks.

- Magnification standards with a certificate;

- Set of probes for various tasks;

No accessories for this product.