HOMMEL TESTER W55

Producer:

- JENOPTIK Industrial Metrology Germany

The most modern device in its class!

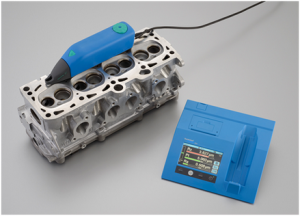

Professional instrument for roughness monitoring of the surface, both in laboratory and in workshop conditions.

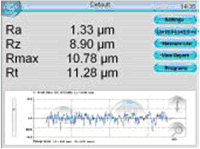

HOMMEL TESTER W55 provides accurate measurement results quickly and easily. Control of the device is oriented to use in the immediate vicinity of the production. Large color touch screen simultaneously displays the parameters, measurement conditions and surface profiles.

HOMMEL TESTER W55 provides professional data management. Measurement protocols are printed on A4 sheets. As an option, the measurement results can be saved electronically as a PDF file. The results are placed in the RAM archive to choose from, where they can be exported via a USB flash drive, or via a local network to the main server memory for storage and subsequent analysis, which can be performed both in Excel files and in QS-STAT® data format.

Functional characteristics

- Robust, functional display

- Measurement of all basic parameters of roughness, profile and waviness parameters

- Tolerance control for all parameters

- Displays P, R, and W profiles, as well as the Abbot curve

- Creating measurement programs on the touch screen

- Managing up to 30 measurement programs

- Built-in statistical functions

- Archiving of measurement results

- Duplicating the device management (from the touch screen or using the function keys)

- Data transfer in ASCII format

- The wavesystem TM provides compatibility of the device with drives having different tracing lengths, as well as with measuring columns (manual and motorized)

SIMPLE CONTROL

Managing all the main functions of the HOMMEL TESTER W55 is carried out using a simple menu.

SHARPNESS OF DISPLAY

A large 10-inch color display displays all the necessary information.

FUNCTIONAL SATURATION

Modern electronic stuffing guarantees the exact result of the received values. The ability to enter individual settings for each of the calculated parameters.

CONSTRUCTION FEATURES

Robust, enclosed aluminum casing and ergonomic design guarantee HOMMEL TESTER W55 “proper operation” both in workshop conditions and in the laboratory.

DATA MANAGEMENT

Measured values are stored in the instrument. Data transfer is possible both on the USB flash card and archiving directly to the server via the local network. The received data can be used in statistical analysis programs of the qs-STAT® type (option). Print the measurement protocol in A4 format to both the connected and the central printer.

COMPATIBILITY

Standard interfaces USB, LAN, WLAN, RS232 allow you to create individual configurations of HOMMEL TESTER W55 for connection with peripheral devices.

ADVANCED FUNCTIONS

Calculation and display of all major profiles, parameters of roughness and waviness in standard equipment. Novelties, functionally-oriented parameters, such as dominant waviness in accordance with VDA 2007, are available as options.

Specifications

| Measuring principle | surface tracing |

| Accuracy class according to DIN 4772 | Class 1 |

| Measuring range/resolution | ± 8 mkm/1 nm, ± 80 mkm/10 nm, ± 400 mkm/50 nm, ± 800 mkm/100 nm |

| Filter: length of cutoff step | 0.025, 0.08, 0.25, 0.8, 2.5, 8 (mm), selectable in the range of -2 to +1 cutoff steps. |

| DIN 4768 | RC, [mm], cutoff step 0.025, 0.08, 0.25, 0.8, 2.5, 8 |

| ISO 11562, Part 1, (50 % Gauss) | Gauss (M1) length of cutoff 0.025, 0.08, 0.25, 0.8, 2.5, 8 |

| ISO 13565-1 2x Gauss (M2) | Rk-parameter, length of cutoff 0,025, 0,08, 0,25, 0,8, 2,5, 8 |

| ISO 3274/11562 | length of short cutoff step of the wave λs, depends on step λc / λs 30, 100, 300 |

| ISO 3274/11562 | filter of the form λf |

| Trace speed vt | lt – nominated 0.05, 0.15, 0.5 mm/sek, measured 0.01 – 2.0 mm/sek with step 0.01 |

| Length of trace lt | 0.48, 1.5, 4.8, 15, 48 mm or it is selected in the range 0.1 – 120 mm, depending on the feed mechanism |

| Length of evaluation ln | 0.40, 1.25, 4.0, 12.5, 40 mm or depending on the cut-off length of the step |

| Cutoff step λ [mm] | 0.08, 0.25, 0.8, 2.5, 8.0 |

| Roughness parameter: ISO 4287 | Ra, Rz, Rmax, Rt, Rq, Rsk, lmo, lo, Rdq, da, ln, La, Lq, Rdc, Rv, Rz-ISO, R3z, Rpm, Rp3z, R3zm, Rp, D, RPc, RSm, Rpm/R3z, lr, Rku, tpif, tpia, tpip, tpic, Rt/Ra, Rz1, Rz2, Rz3, Rz4, Rz5, Rmr, Rmr%, Api |

| Main roughness parameters: ISO 13565 | Rpk*, Rpk, Rk, Rvk*, Rvk, Mr1, Mr 2, A1, A2, Vo(70%)0.01* Rv/Rk |

| Profile parameters: ISO 4287 | Pt., Pp, Pz, Pa, Pq, Psk, PSm, Pdq, lp, Pku, tpaf, tpaa, tpab, tpac, Pmr0, APa, APa%, Pmr, Pmr% |

| Waviness parameters: ISO 4287 | Wt., Wp, Wz, Wa, Wq, Wsk, WSm, Wdq, lw, Wku |

| Motif parameters: ISO 12085 | R, Rx, AR, Nr, W, Wx, AW, Nw, Wte, Tpaf(CR, CL, CF) |

| Roughness parameters: JIS | B – 0601 Rz-JIS, Rmax-JIS |

| Statistics | (n, x, S, R, max, min) for each of 1 – 999 measurements |

| Data output to the monitor and printer | Surface characteristics, statistics, profile position, P-, R-, W-, K-profiles, material curve, measurement conditions, tolerance |

| Peripheral connections | Feeding mechanisms: waveline 20, 60, 120, LV16, Measuring racks: wavelift 400, Data output: 2 x USB (on front panel), 2 x USB (on rare panel), LAN 10/100 (RJ45), RS232 (9-PIN-D-Sub) |

| Power supply | 100 V – 240 V, 50-60 Hz, 160 VА |

| Process temperature | +10°C … + 45°C, max relative humidity 85%, ΔT 2°C/h |

| Storage temperature | -20°C … + 50°C |

Standard kit

HOMMEL TESTER W55-R20-300:

Standard kit

HOMMEL TESTER W55

- 10 “TFT color touch screen

- Keyboard

- LAN interface

- USB interface

Measuring rack

- vertical column 300mm

- granite slab with T-groove 450x280x483 mm (LxWxH)

- rotary support ± 45 °

Drive waveline 20

- tracing length: 20 mm

- deviation from straightness: 0.2 μm / 20 mm

- Motorized positioning of the probe

- Built-in deflection adjustment ± 2 °

A set of test leads TKU300 / 600

- TS1, range ± 300 μm

- TS2, range ± 300 μm

- TS1T for grooves

- TS1D for internal measurement. surfaces of bushings

Geometric reference RNDH 2 with calibration certificate (Ra about 1 μm, Rz about 3.3 μm with calibration certificate)

Manual

HOMMEL TESTER W55-R60-400

Standard kit

HOMMEL TESTER W55

- 10 “TFT color touch screen

- Keyboard

- LAN interface

- USB interface

Measuring rack

- vertical column 300mm

- granite slab with T-groove 450x280x483 mm (LxWxH)

- rotary support ± 45 °

Drive waveline 20

- tracing length: 20 mm

- deviation from straightness: 0.2 μm / 20 mm

- Motorized positioning of the probe

- Built-in deflection adjustment ± 2 °

A set of test leads TKU300 / 600

- TS1, range ± 300 μm

- TS2, range ± 300 μm

- TS1T for grooves

- TS1D for internal measurement. surfaces of bushings

Geometric reference RNDH 2 with calibration certificate (Ra about 1 μm, Rz about 3.3 μm with calibration certificate)

Manual

No accessories for this product.